Cost-Effective Concrete Polishing

A polished concrete floor is indisputable in terms of durability and aesthetic appeal. When you consider the floor’s lifespan, it’s also highly cost-effective. That is why so many people prefer it to other types of flooring. However, not all concrete floors are the same. Polishing and buffing a concrete floor does not guarantee that it will be attractive. You don’t always obtain a lovely result. Why? Because, in essence, polishing concrete can only improve and reveal what is already there. It doesn’t ‘hide’ or ‘cover’ the flaws in the current floor; rather, it highlights them. As a result, if you start with an ugly floor, you’ll wind up with a shinier, better-sealed unattractive floor after polishing.

What Is Concrete Polishing?

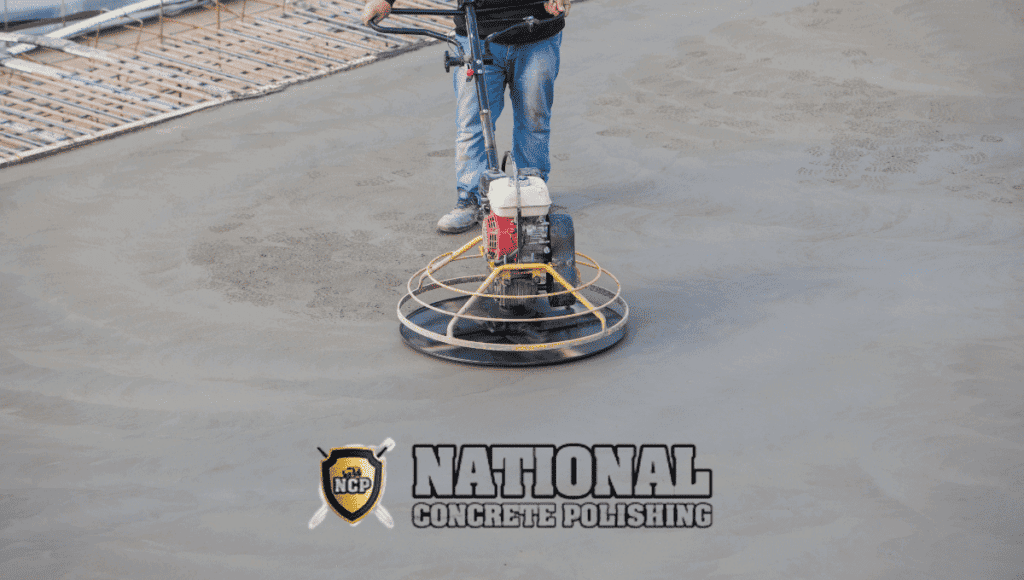

Concrete polishing is the process of grinding down a concrete surface to a desired level of smoothness and shines with heavy-duty floor grinding equipment, similar to sanding wood to create a high-gloss finish. A polished concrete floor , also known as a cement polished floor, is a no-wax flooring material created by rolling a floor grinding machine over a concrete surface – new or old – to achieve a high-gloss finish.

Polished concrete floors are increasingly being used in retail shops, offices, commercial warehouses, and high-end households due to their visual appeal, great durability, and better functionality.

The Pros And Cons Of Polished Concrete Floors

Because of the following advantages, both commercial and residential developers are choosing polished concrete floors over other forms of flooring coverings :

Pros

- Cost-effective: When compared to typical floor coverings, polished concrete floors are more cost effective. It has much lower maintenance costs.

- Various designs are available: Polished concrete floors come in a variety of styles and colors, making them an excellent alternative for homeowners wishing to construct beautiful homes.

- Reflectivity of light. This is a significant advantage for commercial establishments that seek to create a bright, professional image through lighting.

- Transmission of moisture. Concrete polishing allows the surface to breathe, avoiding the problems that might occur when other floor coverings are used to seal the concrete.

- Superior durability and ease of maintenance

Cons

- Hard – The material’s hardness and durability can also be a disadvantage because the surface is extremely hard and will not cushion or “give” under feet, making it uncomfortable to stand on for long periods of time.

- Cold – Concrete floors also have the disadvantage of not retaining heat very effectively….

- Moisture – polishing concrete cannot be done in damp conditions.

- Loud – the machinery used creates a lot of loud sound that can be jarring.

Average Cost

Depending on your region and the complexity of the project, polished concrete might cost anywhere from $3 to $12 per square foot. The cost of polished concrete is determined by how many stages of grinding are required to get a smooth surface. The price of polished concrete may increase depending on the ornamental features used, such as staining or scoring.

Factors That Affect Cost

These price ranges apply to existing concrete grinding, polishing, and ornamental aspects. New concrete installation would be in addition to the price ranges listed above. Here are some more specifics on the elements that influence the ultimate price:

- Gloss or shine level: The tier of shine dictates the number of steps in the polishing process; the glossier the finish, the more steps, and the higher the cost.

- Space: While total square footage certainly translates to the total cost, the price per square foot for larger locations can be significantly lower.

- Currently installed flooring: The cost of the project will increase if the existing flooring needs to be removed. It also has an impact on the expenses of surface preparation. If a floor is currently carpeted or covered in linoleum, for example, there will be adhesive that must be removed.

- Existing surface condition: Before the existing surface can be ground and polished, cracks, holes, and gouges must be rectified. Stains must also be removed, and if the needed repairs are severe, an overlay may be required before polishing. Surface preparation can cost an extra $2 per square foot.

How We Can Help You

One of the most essential parts of a concrete resurfacing project for our customers is the pricing. At National Concrete, we collaborate with you to ensure that you receive the results you desire while staying within your budget—without adding any unexpected fees along the way. To meet today’s trade demands, a diverse range of industrial concrete floor coverings continues to grow and expand. We help you make the best decision. So, call us or visit us on our website for more details.

You might also like

Book a Service Today

We will get back to you as soon as possible

Please try again later

Satisfied Clients

"Jon fixed some flooring issues that I couldn't handle on my own. He was professional, courteous and worked quickly."

MIKE T.

Button

"Adam showed up on time, did the job quickly, and was polite and professional. Would definitely use again."

SHANNON W.

Button

Quick & Reliable

We are available 24/7 via live chat, email or telephone

We proudly use and sell the following products and equipment

We proudly serve the following cities and counties throughout the Dallas Fort Worth area and beyond.

Dallas County Texas- Tarrant County Texas - Collin County Texas - Denton County Texas - Ellis County Texas - Johnson County Texas - Parker County Texas - Kaufman County Texas - Rockwall County Texas - Hunt County Texas - Wise County Texas

Garland Texas - Dallas Texas - Fort Worth Texas - Richardson Texas - Frisco Texas - Farmers Branch Texas

Plano Texas -

McKinney Texas -

Highland Park Texas -

University Park Texas -

Carrollton Texas

Working hours

- Mon - Sun

- Open 24 hours

Navigation

email us

10728 South Pipeline Road

Suite K. Hurst, Texas. 76053

Get a Quote

We will get back to you as soon as possible

Please try again later

All Rights Reserved - Need a lead generating website like this? Contact the webmaster

New Paragraph